White Paper – Improving Calibration Accuracy for High-End Spectroradiometers

The accuracy of a spectroradiometer relies on various factors, including its optical, mechanical, and electronic design, as well as production tolerances. Calibration of the instrument is another crucial factor in achieving accurate spectral measurements. In this white paper, Admesy introduces a new calibration concept that holds promise for enhancing the accuracy of spectroradiometers.

The calibration process for a spectroradiometer involves four steps, with the absolute calibration being the final and an important step. To achieve traceable and absolute calibration, a halogen lamp is used as a reference standard. These lamps are calibrated by renowned national metrology institutes like NIST in the United States or PTB in Germany. However, the uncertainties associated with the calibration data have been a limiting factor in achieving high accuracy for top-tier spectroradiometers. Admesy has developed a patent-pending calibration lamp to address this issue, aiming to reduce uncertainties in calibration data and enable even higher levels of accuracy in spectroradiometric measurements.

The 4 Steps of Spectroradiometer Calibration

During the calibration of a spectroradiometer, the following four steps are performed:

Compensation of Dark Current Noise

The first step involves compensating for dark current noise. This can be accomplished through two methods: conducting a dark measurement with a shutter in place or utilizing an algorithmic approach. Admesy provides a specialized algorithmic solution that ensures both speed and accuracy in compensating for dark current noise. Additionally, the Neo and Prometheus spectroradiometers are equipped with a mechanical shutter, offering users an alternative option for achieving precise calibration.

Calibration of Linearity

The second step focuses on calibrating linearity to ensure accurate measurements at both low and high signal levels. A case study titled “How the Neo Spectrometer Drastically Improves Filter Quality” provides further insights into the importance of good linearity calibration.

Calibration of Wavelength

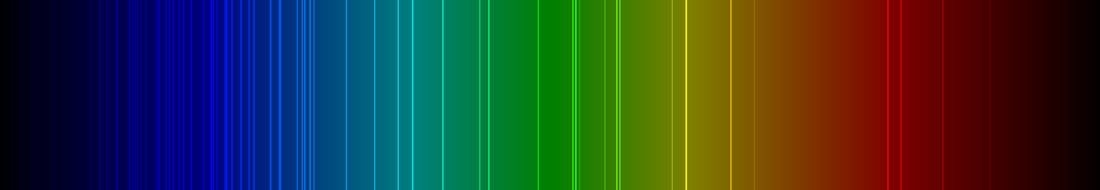

The third step involves calibrating the wavelength using peak light sources with known spectral lines. Examples of such light sources include Cadmium, Krypton, Mercury Argon and others.

Absolute Calibration

The final step is the absolute calibration. A traceable calibration standard, such as a halogen calibration lamp, is used for this purpose. Metrology institutes like PTB measure the calibration lamp and provide quantitative data, including the measurement uncertainties. In the chain of a traceable spectroradiometer calibration, all uncertainties accumulate. As the quantitative data and inherent uncertainties of the calibration lamp are at the initial stage of the calibration chain, the final accuracy of the instrument is ultimately limited by the uncertainties of the traceable calibration lamp.

For example when calculating the uncertainty budget of the spectroradiometer radiance calibration, it is observed that the uncertainties for parameters other than the lamp-related ones are slightly less than 0.5%. On the other hand, the uncertainties related to the lamp are higher in comparison at around 2.5%. Therefore, reducing the uncertainties associated with the lamp can significantly improve the accuracy of the calibrated spectroradiometer.

Characteristics and Limitations of a Conventional Calibration Lamp

In a conventional calibration setup, a lamp emits light through an adjustable aperture into an integrating sphere. The purpose of the sphere is to create a uniform light output at the rear opening. A luminance (Y) sensor is utilized to adjust the light output level before each calibration measurement.

To achieve the utmost accuracy, metrology institutes employ a scanning spectrometer for the calibration process. This measurement typically takes around 8 hours to complete. Throughout the measurement, the spectrum of the light source undergoes two changes. Firstly, the luminance of the light source gradually increases over time as the filament burns off and becomes thinner, resulting in an elevated light output. Secondly, as the filament burns off, it becomes hotter, leading to a spectral tilt (known as blue drift) in the lamp’s spectrum.

The first effect is addressed by averaging the luminance at the beginning and end of the calibration procedure.

However, the second effect is not accounted for, contributing to relatively high uncertainty. The inevitable alteration in the spectral power distribution of the lamp over time is the reason why calibration light sources can only be utilized for approximately 50 hours. This matter required a solution.

Another drawback of halogen calibration lamps is their lower energy output in the short (blue) wavelength region. Consequently, this results in a higher susceptibility to stray light interference for shorter wavelengths.

Admesy Crius Halogen Calibration Light Source: Enhanced Features and Performance

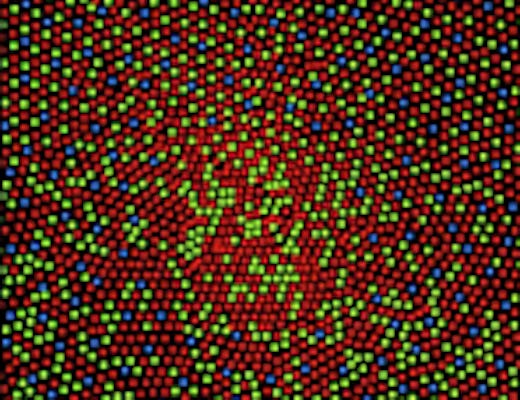

The Admesy Crius Halogen Calibration Light Source offers a solution to the inherent limitations of traditional calibration light sources. Instead of relying on a single luminance (Y) sensor, this innovative device utilizes three sensors, each equipped with multiple bandpass receptors (patent pending).

Admesy has developed these cutting-edge multichannel bandpass sensors in-house, leveraging their extensive experience in filter coating. The advancement made by this patented process enables the monitoring and correction of wavelength tilt (drift) over time, resulting in significantly reduced uncertainty in the calibration data throughout the lamp’s typical 50-hour usage lifespan. Moreover, the improved design allows for prolonged usage beyond 50 hours, effectively reducing the overall cost associated with calibration lamps. Furthermore, the three-sensor setup provides redundancy, ensuring highly accurate tilt correction.

To address the unfavorable spectral power distribution of halogen lamps, a custom “blue enhancement” filter is implemented. This filter effectively reduces the energy ratio between long (red) and short (blue) wavelengths from nearly 6 to a factor of approximately 2. As a result, a better signal-to-noise ratio is achieved, minimizing the influence of stray light in the short wavelength region. This enhancement significantly improves the overall performance of the calibration light source.

A Breakthrough in Calibration: Admesy’s Enhanced Approach Compared to Traditional Methods

Admesy has introduced a groundbreaking calibration concept that surpasses the limitations of conventional calibration light sources. This innovative approach addresses all major aspects of calibration, resulting in significantly reduced uncertainties and a substantial improvement in the achievable accuracy of high-end spectroradiometers. Starting in 2024, this cutting-edge calibration concept will be implemented for both Admesy’s Neo and Prometheus spectrometers, offering users a distinct advantage over existing solutions.

Exclusive Access to the Crius Halogen Calibration Light Source

Moreover, a select group of users will get the opportunity to access the Crius Halogen calibration light source, which incorporates this revolutionary calibration technology. This not only enables the validation of spectroradiometers in production facilities but also simplifies their internal calibration process. If you are interested in learning more or wish to be a part of this exclusive user group, please do not hesitate to contact us.